Tariff-Proof Your Supply Chain: Is Your Business Ready for the Next Trade Shock?

For many businesses, this isn’t just a headline — it’s a deadline !

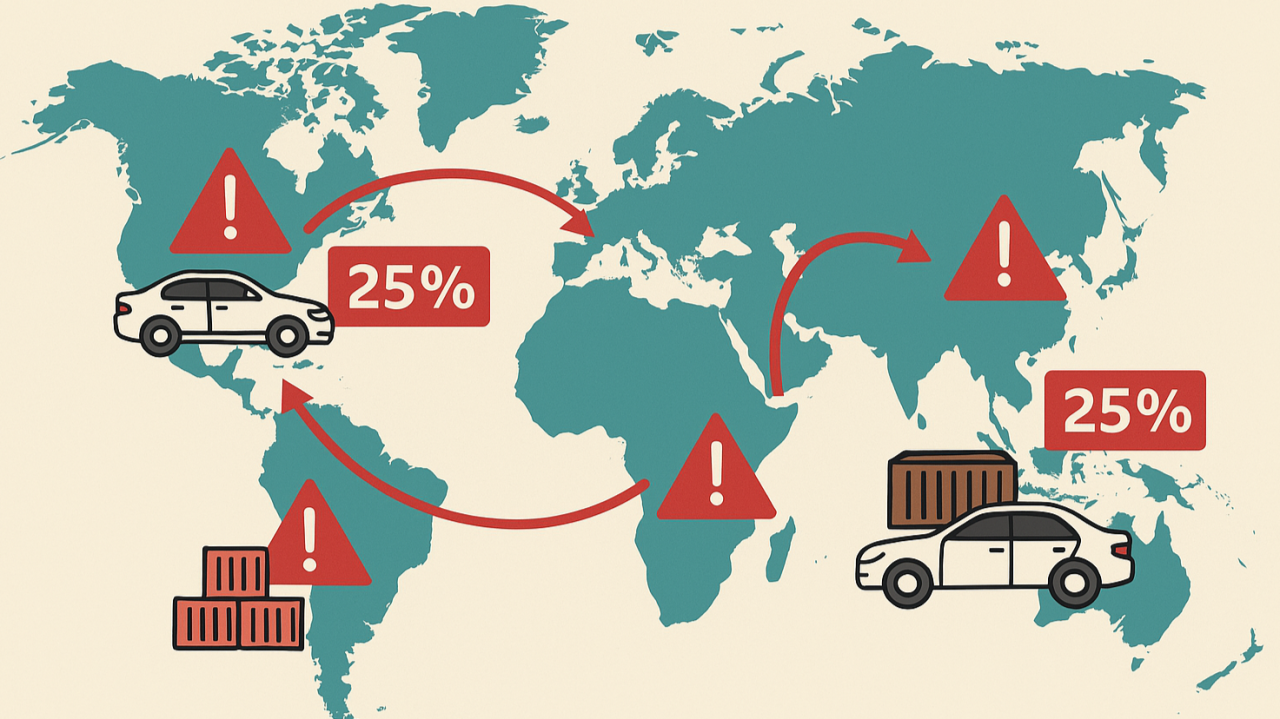

On March 26, a new 25% tariff on imported cars and car parts into the U.S. was announced — set to take effect April 2.

While positioned as a move to strengthen U.S. manufacturing, this policy could trigger a chain reaction of increased costs, supply disruptions, and diplomatic tensions.

For supply chain, sourcing, and manufacturing leaders, this is not just a policy update.

It’s a call to action.

Who Will Feel the Impact First?

- Automakers – Facing cost hikes and operational slowdowns

- Suppliers – Especially cross-border vendors, dealing with tighter margins

- Consumers – Prices projected to rise by $4,000–$10,000 per vehicle

- Exporters – From Mexico, Japan, South Korea, Canada, Germany — all at risk of reduced demand or retaliation

A U.S. International Trade Commission study estimated a 75% drop in car imports and a 5% rise in U.S. vehicle prices with a 25% tariff.

A Pattern We’ve Seen Before

Trade shocks are nothing new. But history shows those who prepare early tend to recover fastest:

2018 Steel & Aluminium Tariffs

- Harley-Davidson shifted production abroad

- GM & Ford warned of U.S. job losses

- The EU and China retaliated with their own tariffs

- Tesla accelerated its Shanghai plant to bypass future disruptions

U.S.–China Trade War

- Apple, GoPro, and others relocated assembly to Vietnam and India

- U.S. soybean and pork exporters lost billions

- Electronics and consumer goods companies restructured their global sourcing

The outcome? Tariffs start as policy, but end as operational chaos — unless businesses act fast.

10 Steps to Tariff-Proof Your Supply Chain

To avoid scrambling at the last minute, here’s how smart businesses are building resilience:

1.Map Critical Imports –Know where each component comes from

2. Scenario Plan – –Model 5%, 15%, and 25% tariff impacts

3.Diversify Suppliers – Build multi-region sourcing redundancy

4.Nearshore Where Possible – Minimize cross-border friction

5.Strategic Inventory – Pre-position stock for lead time risks

6. Negotiate Flex Clauses – Build tariff shock buffers into contracts

7.Track Trade Policy Trends – Don’t get caught flat-footed

8. Digitize Visibility –Real-time alerts on lead times, tariffs, and logistics

9. Redesign Smart – Simplify products or switch to domestic substitutes

10.Align Internally – Keep sourcing, legal, finance & ops on the same page

Final Thought

The next trade disruption is not a question of if, but when. Tariff-proofing isn’t a buzzword — it’s operational insurance.

The most competitive companies in 2025 won’t just be lean — they’ll be prepared.

Tariff-proofing your supply chain isn’t overreaction. It’s risk management, cost control, and strategic foresight rolled into one.